Introduction

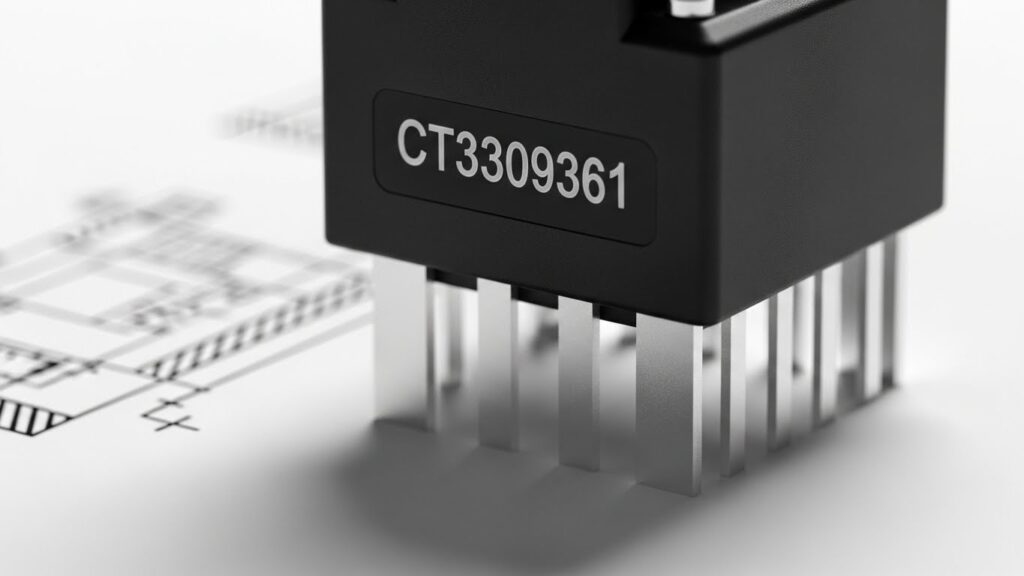

In the complex world of industrial components and electronic parts, specific identifiers like CT3309361 serve as crucial reference points for manufacturers, engineers, and procurement specialists. Understanding what CT3309361 represents, its applications, and its technical specifications can make the difference between project success and costly delays. This comprehensive guide explores everything you need to know about this particular component designation, whether you’re sourcing parts for manufacturing operations, conducting maintenance procedures, or managing inventory systems across industrial facilities.

The CT3309361 identifier follows standardized naming conventions used throughout the electronics and industrial components industry. These alphanumeric codes provide essential information about part specifications, compatibility requirements, and manufacturer details. For professionals working in sectors ranging from automotive manufacturing to telecommunications infrastructure, familiarity with component identifiers like CT3309361 ensures accurate ordering, proper installation, and reliable system performance. This article breaks down the technical aspects, practical applications, and procurement considerations surrounding this component designation, providing actionable insights for engineers, technicians, and supply chain managers who need to make informed decisions about component selection and implementation in their respective projects.

Understanding Component Identification Systems

Modern industrial and electronic components rely on sophisticated identification systems that enable precise tracking, ordering, and quality control throughout global supply chains. The CT3309361 designation represents one such identifier within this comprehensive framework. These alphanumeric codes typically encode specific information about the component’s manufacturer, product line, technical specifications, and sometimes even production batch details. Understanding how to decode these identifiers helps professionals quickly assess whether a particular part meets project requirements without consulting extensive documentation.

Component identification systems have evolved significantly over the past several decades, driven by increasing complexity in manufacturing processes and the need for international standardization. The CT3309361 format follows industry-standard conventions that facilitate communication between manufacturers, distributors, and end users across different regions and technical disciplines. When engineers encounter this designation in technical drawings, bills of materials, or procurement requests, they can leverage established databases and manufacturer resources to obtain detailed specifications. This systematic approach reduces errors in component selection, minimizes compatibility issues during installation, and supports efficient inventory management practices across organizations of all sizes.

Read More: Бесарабинформ

Technical Specifications and Performance Characteristics

Every component identifier like CT3309361 corresponds to specific technical parameters that define its operational capabilities and limitations. These specifications typically include electrical characteristics such as voltage ratings, current handling capacity, resistance values, or capacitance measurements depending on the component type. Mechanical specifications like physical dimensions, mounting requirements, and environmental tolerances are equally important for ensuring proper integration into existing systems. Understanding these technical details is essential for engineers who must evaluate whether the CT3309361 component meets the precise requirements of their application.

Performance characteristics extend beyond basic specifications to include factors such as operating temperature ranges, expected lifespan under typical conditions, and reliability ratings based on industry-standard testing protocols. For the CT3309361 designation, consulting manufacturer datasheets provides comprehensive information about performance curves, degradation patterns over time, and recommended operating conditions that maximize component longevity. Engineers conducting design reviews or failure analysis investigations rely heavily on this technical data to make informed decisions about component selection, redundancy requirements, and maintenance scheduling. Additionally, understanding performance characteristics helps procurement teams evaluate cost-effectiveness by balancing initial component prices against long-term reliability and replacement frequencies in real-world operating environments.

Common Applications and Industry Usage

Components identified by designations such as CT3309361 find applications across diverse industrial sectors, each with unique requirements and operating conditions. In manufacturing environments, these components might serve critical functions in control systems, automation equipment, or quality monitoring devices that ensure production consistency. The telecommunications industry frequently utilizes specialized components for signal processing, network infrastructure, and data transmission equipment where reliability and performance consistency are paramount. Understanding the typical application contexts for CT3309361 helps professionals assess whether this component aligns with their specific project needs.

Automotive systems represent another significant application area where precisely specified components play vital roles in safety systems, engine management, and vehicle electronics. Aerospace and defense applications demand components that meet rigorous qualification standards for performance under extreme conditions, including temperature variations, vibration, and electromagnetic interference. The CT3309361 component may also appear in medical devices, industrial process control systems, or renewable energy installations, depending on its technical characteristics and certification status. Each industry sector imposes distinct requirements regarding component traceability, quality certifications, and long-term availability, making it essential for procurement professionals to verify that the CT3309361 designation meets applicable industry standards and regulatory requirements before committing to large-volume purchases or critical system integrations.

Procurement Strategies and Supply Chain Considerations

Successful procurement of components like CT3309361 requires careful attention to supplier selection, pricing dynamics, and availability forecasting. Authorized distributors provide assurance of genuine components with full manufacturer warranties and technical support, while alternative sourcing channels may offer cost advantages but carry increased risks of counterfeit or substandard parts. Establishing relationships with multiple suppliers for the CT3309361 component creates supply chain resilience, protecting against disruptions from single-source dependencies or regional supply constraints that can halt production operations.

Lead times for component delivery vary significantly based on manufacturer production schedules, distributor inventory levels, and global logistics conditions. Strategic procurement teams monitor these factors continuously, adjusting order quantities and timing to maintain optimal inventory levels without excessive capital tied up in unused stock. For the CT3309361 designation, understanding typical lead times and identifying potential obsolescence risks enables proactive planning for product redesigns or component substitutions when necessary. Volume pricing negotiations, framework agreements with preferred suppliers, and participation in industry consortiums can yield significant cost savings over time. Additionally, implementing robust inventory management systems with accurate tracking of CT3309361 components across multiple storage locations prevents stockouts while minimizing carrying costs and reducing risks of component aging or damage during extended storage periods.

Quality Assurance and Testing Protocols

Ensuring that components bearing the CT3309361 designation meet required quality standards demands comprehensive testing protocols at multiple stages of the supply chain. Incoming inspection procedures verify that received components match specifications documented in purchase orders and manufacturer datasheets, checking for physical damage, correct markings, and proper packaging. Advanced testing may include electrical parameter verification, environmental stress screening, or sample destructive testing to validate manufacturing quality and detect potential counterfeit components that could compromise system reliability.

Quality assurance extends beyond initial receipt to encompass storage conditions, handling procedures, and installation practices that affect component performance and longevity. Electrostatic discharge protection, humidity control, and temperature management in storage facilities preserve the integrity of the CT3309361 component until deployment. During installation, following manufacturer-recommended practices for soldering temperatures, mechanical mounting torques, and electrical connections prevents damage that might not become apparent until field failures occur months or years later. Documented quality procedures create traceability from component receipt through final system testing, supporting root cause analysis when failures occur and providing evidence of due diligence for regulatory compliance or liability considerations. Organizations that prioritize quality assurance for components like CT3309361 experience fewer field failures, reduced warranty costs, and enhanced reputation for product reliability in competitive markets.

Troubleshooting and Maintenance Best Practices

When systems incorporating the CT3309361 component exhibit performance issues or failures, systematic troubleshooting approaches identify root causes efficiently and guide effective corrective actions. Initial diagnostic steps typically include visual inspection for obvious damage, verification of proper electrical connections, and measurement of operating parameters using calibrated test equipment. Comparing actual measurements against specifications from manufacturer datasheets reveals whether the CT3309361 component has degraded, been damaged, or was incorrectly specified for the application. Environmental factors such as excessive temperature, moisture exposure, or electrical overstress frequently contribute to component failures and must be investigated thoroughly.

Preventive maintenance programs extend the operational life of systems containing components like CT3309361 by addressing potential problems before failures occur. Regular inspections identify early warning signs such as discoloration, corrosion, or mechanical wear that indicate impending failure. Predictive maintenance techniques including thermal imaging, vibration analysis, or electrical parameter trending detect gradual degradation patterns that allow scheduled replacement during planned downtime rather than emergency repairs. Maintaining accurate maintenance records for the CT3309361 component supports reliability analysis, warranty claims, and continuous improvement initiatives that optimize system performance. When replacement becomes necessary, using genuine components with verified specifications and proper installation procedures restores system performance to original design parameters. Documentation of troubleshooting activities and corrective actions builds organizational knowledge that improves response times for future issues and informs design improvements in next-generation systems.

Future Trends and Technology Evolution

The landscape surrounding component identification and management continues evolving rapidly, driven by advances in digital technologies, artificial intelligence, and Internet of Things connectivity. Smart components with embedded sensors and communication capabilities may eventually replace passive parts like the CT3309361 designation represents today, enabling real-time health monitoring and predictive failure alerts. Blockchain-based supply chain tracking promises enhanced authentication and traceability, addressing persistent concerns about counterfeit components that compromise system reliability and safety. These technological shifts will reshape how engineers specify components, how procurement teams source and verify parts, and how maintenance personnel monitor and manage installed equipment.

Standardization efforts across international organizations work continuously to harmonize component identification systems, improve interoperability, and establish universal databases that simplify cross-referencing between different manufacturer part numbers. For components in the same category as CT3309361, these initiatives may eventually enable more seamless substitution across suppliers, reducing supply chain risks and fostering greater competition that benefits end users through lower prices and improved availability. Environmental regulations driving reductions in hazardous substances, improved recyclability, and lower energy consumption influence component design and manufacturing processes, potentially leading to revised specifications or entirely new component families. Professionals working with components like CT3309361 must stay informed about these trends, participating in industry forums, maintaining relationships with technology providers, and investing in continuous learning to ensure their organizations remain competitive in rapidly changing technical and business environments.

Conclusion

Navigating the complexities surrounding component identifiers like CT3309361 requires comprehensive knowledge spanning technical specifications, procurement strategies, quality assurance practices, and industry trends. This guide has explored the multifaceted aspects of working with such components, from understanding identification systems and technical parameters to implementing effective sourcing and maintenance programs. Whether you’re an engineer designing new systems, a procurement professional managing supply chains, or a technician maintaining critical equipment, mastery of these concepts directly impacts project success, operational reliability, and organizational competitiveness.

As technology continues advancing and supply chains become increasingly global and complex, the importance of systematic approaches to component management only grows stronger. By applying the insights and best practices outlined in this article, professionals can make more informed decisions about the CT3309361 component and similar designations they encounter in their work. Staying current with industry developments, maintaining strong supplier relationships, and prioritizing quality throughout the component lifecycle position organizations for sustained success in demanding technical environments where reliability and performance cannot be compromised.