Introduction

In the world of precision engineering and industrial manufacturing, the term “spezialbohrgetriebe” represents a cornerstone technology that many professionals rely on daily, yet few outside specialized circles fully understand. Translating to “special drilling gearbox” in English, this sophisticated component serves as the mechanical heart of countless drilling operations across diverse industries. Whether you’re fabricating aerospace components, constructing heavy machinery, or producing automotive parts, the spezialbohrgetriebe provides the torque conversion, speed regulation, and precision control that modern manufacturing demands.

The evolution of drilling technology has been remarkable over the past few decades. What began as simple mechanical systems has transformed into highly engineered solutions capable of handling extreme loads, variable speeds, and incredibly tight tolerances. At the center of this transformation sits the spezialbohrgetriebe—a specialized gearbox designed specifically to optimize drilling performance in applications where standard transmission systems simply fall short. These units combine advanced gear ratios, robust construction materials, and precision engineering to deliver consistent results even under the most demanding conditions.

Understanding how spezialbohrgetriebe systems function and where they provide the greatest value can significantly impact your manufacturing efficiency, product quality, and operational costs. From automotive assembly lines in Detroit to aerospace facilities in Seattle, these specialized drilling gearboxes continue to prove their worth as indispensable tools for achieving manufacturing excellence.

Understanding Spezialbohrgetriebe Technology and Its Core Principles

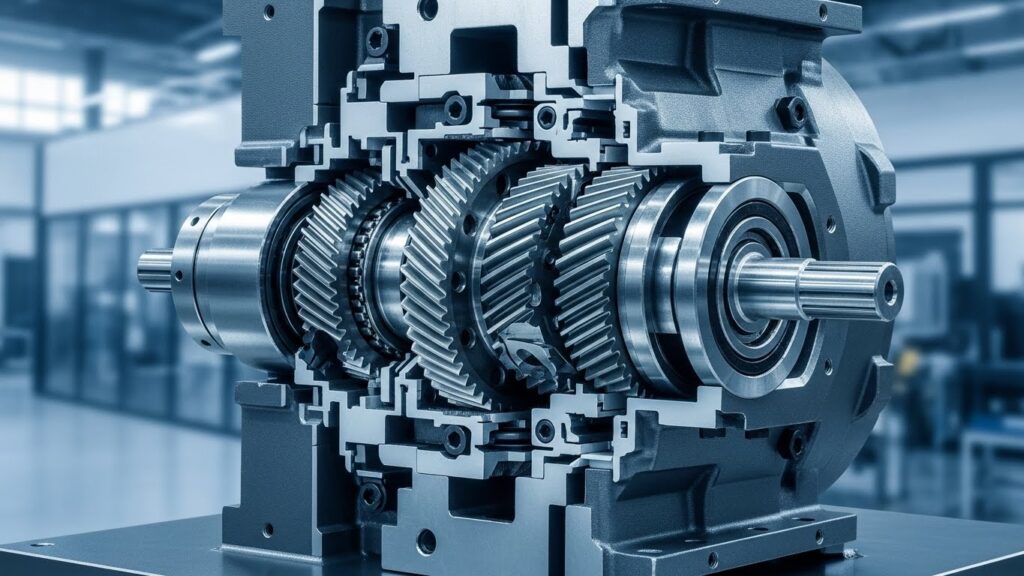

The fundamental design of a spezialbohrgetriebe centers on converting input power into optimized drilling performance through carefully calculated gear ratios and mechanical configurations. Unlike conventional gearboxes that serve general-purpose applications, these specialized units are engineered with drilling-specific requirements in mind. They account for variables such as material hardness, drill bit diameter, feed rates, and the thermal loads generated during extended drilling operations. The internal architecture typically features hardened steel gears, precision bearings, and cooling channels that work in concert to maintain performance integrity even when operating continuously for hours.

What distinguishes a quality spezialbohrgetriebe from inferior alternatives is the attention to manufacturing tolerances and material selection. Premium units utilize case-hardened alloy steels for gear teeth, ensuring longevity even when subjected to shock loads and reversing cycles. The housing design incorporates ribbing patterns that enhance structural rigidity while facilitating heat dissipation—a critical factor when drilling through materials like titanium or hardened steel. Many modern designs also integrate electronic monitoring systems that track temperature, vibration, and load parameters, providing operators with real-time feedback about gearbox health. This proactive approach to maintenance helps prevent catastrophic failures that could result in costly downtime and damaged workpieces. Engineers selecting a spezialbohrgetriebe for their application must carefully balance factors including torque requirements, speed ranges, mounting configurations, and environmental conditions to ensure optimal performance.

Read More: Brianchavez85

Key Industries Relying on Spezialbohrgetriebe Solutions

The aerospace manufacturing sector represents one of the most demanding applications for spezialbohrgetriebe technology. When drilling holes in aircraft structural components, bulkheads, or engine mounts, manufacturers face stringent requirements for hole placement accuracy, surface finish quality, and perpendicularity. A single misplaced or poorly executed hole can compromise structural integrity or aerodynamic performance. Specialized drilling gearboxes used in aerospace applications often feature multiple speed ranges, allowing operators to optimize cutting speeds for materials ranging from aluminum alloys to carbon fiber composites. The precision and repeatability offered by these units directly translates to reduced scrap rates and improved aircraft safety.

Heavy equipment manufacturing and shipbuilding industries similarly depend on robust spezialbohrgetriebe systems to handle the extreme demands of their applications. When fabricating components for excavators, cranes, or naval vessels, manufacturers routinely drill through steel plates exceeding several inches in thickness. These operations generate tremendous cutting forces and substantial heat, requiring drilling gearboxes with exceptional torque capacity and thermal management capabilities. Shipyards along the Gulf Coast and Great Lakes regions have increasingly adopted advanced spezialbohrgetriebe technology to improve productivity while maintaining the structural integrity required for vessels operating in challenging maritime environments. The automotive industry also represents a significant market segment, where these specialized gearboxes facilitate high-volume drilling operations on engine blocks, transmission housings, and chassis components. The combination of speed, precision, and reliability that modern spezialbohrgetriebe systems deliver has become essential for manufacturers competing in today’s cost-conscious automotive marketplace.

Technical Specifications That Define Performance Standards

When evaluating a spezialbohrgetriebe for a specific application, several critical technical specifications demand careful consideration. Torque capacity stands as perhaps the most fundamental parameter—this value indicates the maximum rotational force the gearbox can transmit without risking mechanical failure or excessive wear. Industrial drilling operations involving large-diameter bits or hard materials require gearboxes capable of delivering substantial torque at relatively low rotational speeds. Conversely, applications involving smaller bits in softer materials prioritize higher speed ranges over raw torque. The gear ratio selection within a spezialbohrgetriebe determines this speed-to-torque conversion, with common ratios ranging from 3:1 for high-speed applications to 20:1 or higher for maximum torque delivery.

Duty cycle rating provides another essential specification that often receives insufficient attention during the selection process. This parameter defines how long the spezialbohrgetriebe can operate continuously at rated load before requiring a rest period for cooling. Industrial applications involving continuous production runs demand gearboxes rated for 100% duty cycles, meaning they can operate indefinitely without thermal limitations. Input and output shaft configurations also significantly impact installation flexibility and application compatibility. Common arrangements include coaxial designs where input and output shafts align along the same axis, right-angle configurations that redirect power flow ninety degrees, and parallel shaft designs offering offset mounting capabilities. Bearing specifications, lubrication requirements, and sealing arrangements round out the technical considerations that determine whether a particular spezialbohrgetriebe will deliver reliable long-term performance in your specific operating environment. Manufacturers providing comprehensive technical documentation and application engineering support help ensure proper specification and installation.

Maintenance Best Practices for Extended Service Life

Implementing a proactive maintenance program represents the most effective strategy for maximizing spezialbohrgetriebe longevity and minimizing unexpected downtime. Regular lubrication stands as the cornerstone of any maintenance regimen, as proper oil viscosity and cleanliness directly impact gear tooth durability and bearing life. Most manufacturers specify lubricant change intervals based on operating hours, though conditions involving high temperatures, contaminated environments, or heavy shock loads may necessitate more frequent service. Synthetic lubricants formulated specifically for enclosed gear drives often provide superior performance compared to conventional petroleum-based oils, particularly in applications subject to wide temperature swings or where extended drain intervals offer significant operational advantages.

Vibration analysis and thermal monitoring provide valuable diagnostic information about spezialbohrgetriebe condition between scheduled maintenance intervals. Baseline measurements taken when the unit is new establish reference points for comparison as operating hours accumulate. Gradual increases in vibration amplitude or shifts in frequency spectrum patterns often indicate developing problems such as bearing wear, gear tooth damage, or misalignment issues. Similarly, abnormal temperature rises may signal inadequate lubrication, excessive loading, or deteriorating seals that allow contaminant ingress. Many facilities have implemented predictive maintenance programs that leverage these monitoring technologies to transition from reactive repair approaches to condition-based servicing strategies. This shift not only reduces maintenance costs but also prevents secondary damage that often occurs when a failing spezialbohrgetriebe continues operating until catastrophic failure. Documentation of maintenance activities, including lubricant analysis results and vibration trends, creates a valuable historical record that aids troubleshooting and helps optimize service intervals for specific applications.

Emerging Innovations Shaping the Future of Drilling Gearboxes

The integration of smart sensors and Industrial Internet of Things (IIoT) connectivity represents a transformative trend in spezialbohrgetriebe technology. Modern units increasingly feature embedded sensors that continuously monitor parameters including temperature, vibration, load, and rotational speed. This data streams wirelessly to centralized monitoring systems where advanced algorithms analyze trends and generate predictive maintenance alerts before problems escalate into failures. Manufacturers can now track fleet-wide performance metrics, identify underperforming units, and optimize operational parameters across multiple facilities. This connectivity also enables remote diagnostics, allowing equipment suppliers to provide technical support without requiring on-site visits—a capability that proved particularly valuable during recent supply chain disruptions.

Materials science advances continue to push the boundaries of what spezialbohrgetriebe designs can achieve. Researchers are exploring exotic alloys and surface treatments that promise enhanced wear resistance, reduced friction, and improved thermal characteristics. Some experimental designs incorporate ceramic components in bearing assemblies, offering the potential for dramatically extended service intervals in applications where contamination or extreme temperatures limit conventional bearing life. Additive manufacturing technologies are also making inroads, enabling the production of complex internal geometries that would be impossible to machine using traditional methods. These 3D-printed components can integrate cooling channels, weight-reduction lattice structures, and optimized stress distribution features that enhance overall spezialbohrgetriebe performance. As these technologies mature and production costs decline, they promise to democratize access to custom-engineered solutions that were previously economically viable only for high-volume applications. The convergence of digitalization, advanced materials, and innovative manufacturing processes positions the spezialbohrgetriebe as a technology poised for continued evolution and expanded capabilities.

Selection Criteria for Optimal Application Matching

Choosing the appropriate spezialbohrgetriebe for a specific drilling application requires a systematic evaluation of operational requirements against available product offerings. Begin by clearly defining the performance envelope your application demands, including maximum drilling diameter, material hardness ranges, required feed rates, and expected production volumes. These parameters directly influence torque requirements and speed range specifications. Environmental factors deserve equal consideration—will the gearbox operate in climate-controlled manufacturing facilities or harsh outdoor environments subject to temperature extremes, moisture exposure, or contamination? Such conditions necessitate specialized sealing arrangements, corrosion-resistant materials, and possibly explosion-proof enclosures for hazardous locations.

Mounting configuration and space constraints often emerge as deciding factors when narrowing down spezialbohrgetriebe options. Machine tool design may dictate specific input and output shaft orientations, footprint limitations, or attachment interfaces. Retrofitting existing equipment with upgraded gearboxes introduces additional constraints regarding bolt patterns, shaft dimensions, and overall envelope dimensions. Beyond the mechanical specifications, consider the total cost of ownership rather than focusing solely on initial purchase price. A premium spezialbohrgetriebe with superior efficiency characteristics may consume less energy over its service life, while robust construction and quality bearings extend maintenance intervals and reduce lifecycle costs. Manufacturer support capabilities including technical assistance, spare parts availability, and warranty terms provide additional value that should factor into your decision process. Engaging with application engineers early in the selection process helps identify potential issues and ensures the chosen spezialbohrgetriebe integrates seamlessly into your manufacturing operation. Many suppliers offer application testing programs where you can evaluate equipment performance with your actual workpieces before committing to purchase—an invaluable resource for high-stakes applications where performance validation justifies the additional time investment.

Troubleshooting Common Operational Issues

Even well-maintained spezialbohrgetriebe units occasionally develop performance issues requiring systematic diagnosis and corrective action. Excessive noise represents one of the most common complaints, with potential causes ranging from inadequate lubrication and contaminated oil to worn bearings or damaged gear teeth. Distinguishing between these possibilities requires careful observation of when the noise occurs, its frequency characteristics, and whether it correlates with specific load conditions or rotational speeds. Grinding or crunching sounds typically indicate more severe problems such as gear tooth damage or bearing failure, demanding immediate shutdown to prevent catastrophic damage. Whining or whistling noises at specific speeds may point to gear tooth contact pattern issues or resonance phenomena that, while annoying, may not threaten immediate failure.

Overheating presents another frequent concern that can stem from multiple root causes. Insufficient lubrication—whether from low oil levels, degraded lubricant quality, or inadequate circulation—ranks as the most common culprit. However, excessive ambient temperatures, blocked cooling fins, or operation beyond rated capacity can also generate thermal problems. When investigating overheating issues, measure and record actual operating temperatures using calibrated instruments rather than relying on subjective assessments. Compare these readings against manufacturer specifications to determine whether a genuine problem exists. Unexpected changes in drilling performance, such as reduced feed rates or difficulty maintaining depth tolerances, may indicate problems within the spezialbohrgetriebe even when no obvious symptoms like noise or heat are present. These situations often reflect internal wear that has accumulated gradually, altering gear tooth contact patterns or increasing internal clearances. Systematic troubleshooting combining visual inspections, performance measurements, and diagnostic testing helps identify root causes efficiently, minimizing downtime and preventing misguided repair attempts that address symptoms rather than underlying problems.

Conclusion

The spezialbohrgetriebe represents far more than just another mechanical component—it embodies the precision engineering and specialized design thinking that separates adequate drilling operations from truly exceptional ones. Throughout manufacturing sectors ranging from aerospace to heavy equipment fabrication, these specialized drilling gearboxes deliver the torque control, speed regulation, and reliability that modern production demands. As we’ve explored, selecting the right unit requires careful attention to technical specifications, application requirements, and operational environments. Equally important is implementing maintenance best practices that protect your investment and maximize service life.

Looking forward, emerging technologies including smart sensors, advanced materials, and digital connectivity promise to expand spezialbohrgetriebe capabilities even further. Manufacturers who embrace these innovations position themselves to achieve new levels of productivity, quality, and operational efficiency. Whether you’re specifying equipment for a new facility or upgrading existing machinery, the time invested in understanding spezialbohrgetriebe technology pays dividends through improved drilling performance, reduced operating costs, and enhanced product quality. Consider consulting with application engineers and equipment specialists to ensure your drilling operations benefit from the precision and reliability that properly selected and maintained specialized drilling gearboxes deliver.